Many of us might not realize that neglecting our trolling motor's electrical system can substantially reduce its lifespan. Indeed, thorough maintenance isn't just about keeping the motor running; it's about achieving peak performance every time we hit the water. We all want a hassle-free experience that translates into better fishing days. Could there be a direct connection between how we manage this essential component and the reliability of our fishing trips? There's a lot more at stake than just turning the propeller, and we'll explore how to guarantee exceptional operation every time.

Understanding Your Trolling Motor

Understanding our trolling motor is essential, as it's the heart of our fishing endeavors. The right motor selection lets us glide silently across the water, making it easier to sneak up on those finicky fish.

With choices like bow-mounted, transom-mounted, and engine-mounted, we need to pick the type that matches our fishing strategies and boat design. Bow-mounted motors give us excellent control, perfect when we're stealthily pursuing bass. Transom-mounted ones suit smaller boats, offering versatility and ease of attachment. Engine-mounted motors eliminate clutter on the deck, aligning with our journey toward freedom on open waters.

Proper cable size for the trolling motor is crucial to ensure efficient power delivery and safety. Every trolling motor type plays a distinct role and it's critical we align our choice with our fishing tactics. Do we want precision control? Or maybe versatility in positioning is our go-to strategy?

Letting our motor complement our fishing style aids in crafting unforgettable experiences on our favorite lakes and rivers. As we face varied fishing conditions, having a deep understanding of how each motor can optimize our technique is empowering.

Together, we make decisions that enhance our adventures, all starting with the perfect motor choice tailored to our needs and aspirations.

Inspecting Electrical Connections

As we glide across serene waters, largely thanks to our trusty trolling motor, making sure its electrical system runs smoothly becomes a necessary endeavor.

To keep our adventures uninterrupted, let's focus on inspecting electrical connections. First, corrosion prevention is key. We should check our connections regularly for any signs of corrosion or oxidation, which can lead to performance decline. It's important to note that inspecting cables and wires for wear or frays ensures safe and efficient operation.

A simple connection cleaning with a brush or cloth can remove debris and keep everything in top shape.

Securing connections is another vital step. We must guarantee they're tight to prevent those dreaded performance issues. If we're noticing a drop in power or strange noises, it could point to faulty connections.

Using a multimeter, we can test the voltage for any inconsistencies or breaks that need attention.

Additionally, a visual inspection helps us spot any cracks or frays, and tracing wires can reveal breaks. On finding anything that seems off, we replace damaged wiring immediately.

Steer clear of potential problems by incorporating some preventative measures—regular maintenance and moisture protection go a long way. If things get too tricky, reaching out for professional assistance guarantees our motor's electrical system is always ready for the next great escape.

Battery Maintenance Tips

To guarantee our trolling motor keeps humming efficiently across the water, focusing on battery maintenance is crucial. We want our adventures to be smooth and uninterrupted, right? Let's plunge into some essential tips to keep our battery health in check.

First, adopt the right charging techniques. Always prioritize safety by charging batteries in well-ventilated areas—no one wants a mishap.

Use a charger that matches our battery type, whether it's lead-acid or lithium-ion. Keep the connections secure and monitor the charging process to avoid overheating. It's best to avoid those extremes and heated summer sunlight when charging.

Maintaining battery health also means regular check-ups. Cleaning connections helps prevent corrosion. Following a battery maintenance schedule by performing tasks every three months can significantly enhance the life and reliability of the motor.

Use a multimeter to check the voltage; around 12.6 volts signals a happy, full battery. We can't ignore the importance of preventing deep discharges, so keeping our battery charges above 50 percent is key.

And remember, if the battery looks cracked or leaky, it's time for a replacement.

Finally, store our batteries in cool, well-ventilated areas, and check their voltage every few months. With these simple steps, we'll confirm our trolling motor stays powerful and ready for our next adventure.

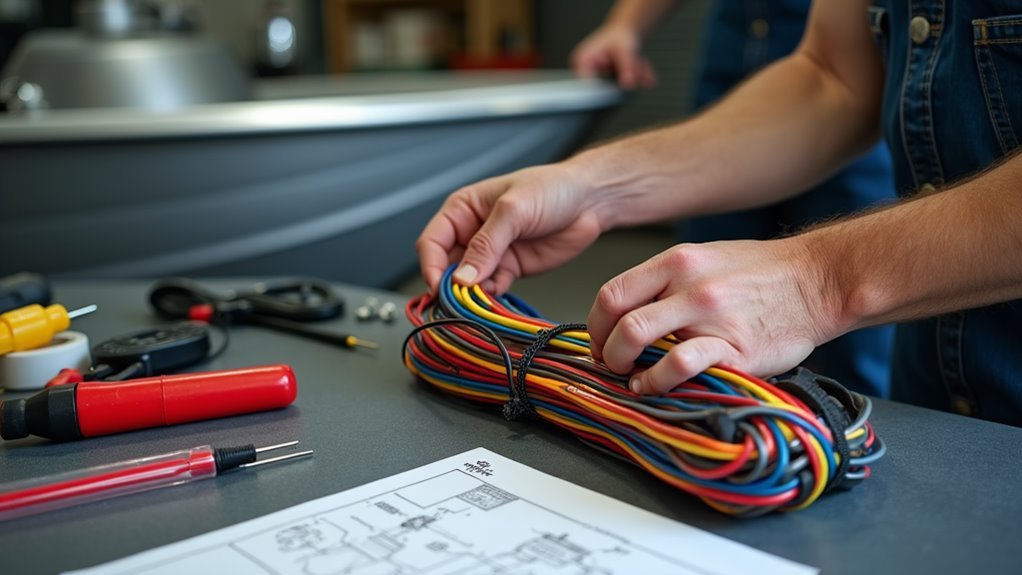

Wiring and Cable Care

Our trolling motor's wiring and cable system is pivotal in ensuring smooth and consistent operation. First, let's talk about cable routing. Routing our cables away from other electrical wirings on the boat is essential. This way, we avoid interference that might cause our motor to flicker or stutter when we least expect it.

Using wire insulation techniques is equally important to prevent accidental shorting. We wouldn't want to find ourselves stranded on the water because of something so easily avoidable.

Let's delve into how we can properly care for these essential components. Opting for the right gauge cables is important; we should use 10-gauge battery cables and switch to 8-gauge if we run longer than six feet. Regular maintenance of our boat's electrical system, including battery maintenance, prevents potential issues while ensuring optimal performance. Checking the cables regularly for any signs of damage, like frayed ends or cuts, keeps us a step ahead. It's imperative to keep them organized, using cable ties for neatness, ensuring they don't interfere with transducer cables or get pinched.

Keeping our cables away from heat sources and making sure they're secured against sharp edges helps prevent overheating and damage, protecting our motor as we glide freely through the water.

Secure Rigging Practices

When it comes to guaranteeing secure rigging practices, proper installation and mounting play a crucial role in keeping our trolling motor stable and efficient. It all starts with choosing a sturdy mounting bracket. We'll want one that's durable and relies on minimal plastic parts. Electric trolling motors can provide substantial thrust power with correct installation, enabling boats to hold position even in challenging conditions. Pair this with a composite or stainless steel shaft for the best shock resistance and durability. Mounting considerations are key, especially for those bow mount motors. They'll need a flat platform at the boat's front and guarantee there's enough room for fishing activities.

Cable routing is another important aspect we can't overlook. We need to make sure cables are neatly secured and free from abrasion, so they don't get damaged. Properly covering any exposed wiring with marine-grade silicone and using water-resistant covers will help keep connections safe from the elements.

For batteries, let's aim for a secure placement using a ventilated crate or container with quick-release buckles, keeping them both easy to access and safe from water exposure.

Embracing these secure rigging practices guarantees we're free to explore waters confidently, knowing our trolling motor setup is reliable and ready for any adventure we choose.

Signs of Electrical Issues

Electrical issues in a trolling motor can often be frustrating, but by paying close attention to signs like inconsistent power delivery and performance surges, we can nip potential problems in the bud. When we experience electrical noise or sudden voltage drops, it often signals trouble.

Intermittent power loss might be due to wiring issues or corrosion in the connectors. Such glitches can disrupt our freedom on the water, forcing unwanted pauses or power failures mid-adventure.

Surging or inconsistent performance can be attributed to corrosion, failing breakers, or issues in the wiring path. Keeping an eye out for these signs helps us maintain a smooth cruising experience. Surges might occur if dirty or corroded battery connections resist ideal current flow. Over time, issues like a rubbed and cut wire can arise, necessitating tool-assisted repairs for consistency. This can result in our motor struggling or losing power.

Low voltage or inadequately charged batteries are also culprits leading to weak performance.

It's essential that we inspect our motor, looking for obvious damage or breaks in wiring, and use tools like test lights to verify power continuity. By understanding and addressing these signs early, we can preserve our motor's performance and continue enjoying our freedom on the waters.

Importance of Circuit Protection

Ensuring the integrity of a trolling motor's electrical system hinges substantially on robust circuit protection. To experience true freedom on the water, we need to grasp the significance of fuse selection and breaker types for our trolling motors. Properly selected fuses and breakers guarantee that our system withstands any surprising currents without overheating or causing dangerous failures. We all know the freedom that comes with peace of mind, so let's protect our valuable investment.

When we talk about fuse selection, it's vital to choose one that matches the maximum amp draw of the trolling motor. This safeguards protection against overheating, safeguarding both the motor and internal wiring from damage. Ensure that the fuse size correlates properly with the wire gauge to prevent excessive heat or fire risks. Maxi fuses are our top choice here due to their reliability and effectiveness. In respect of breaker types, let's avoid auto-reset breakers, as they can lead to repeated tripping and more harm.

Instead, manual reset breakers or appropriate fuses are our best options for isolating circuits and protecting individual loads.

Troubleshooting Common Problems

Understanding robust circuit protection is only part of keeping our trolling motor's electrical system in top shape.

We often face common issues that can be resolved with some basic electrical diagnostics and a keen eye for system optimization. Let's plunge into troubleshooting steps to guarantee our motor runs smoothly.

1. Check Battery Performance: We start by using a multimeter to test the battery voltage; it should read around 12.6 volts when fully charged.

If our battery has cracks or leaks, it's time to replace it. Battery age is crucial since they typically last 2-5 years. Corrosion issues may lead to poor power delivery and require attention to ensure optimal battery function.

2. Identify Connection Problems: Clean and secure connections are essential.

We should inspect for any corrosion at terminal points. It helps to use fine sandpaper for cleaning.

Also, guarantee wires aren't undersized or overheating.

3. Evaluate System Performance: A load test can help us understand how well our battery holds up under use.

Let's check for parasitic drains by guaranteeing no devices are pulling power when not in use, and monitor our motor for consistent speed and power.

These steps will guide us in maintaining freedom of movement on our water adventures.

Seasonal Maintenance Checklist

As we prepare for seasonal changes, it is crucial to routinely check our trolling motor to keep it in peak condition. Our seasonal maintenance checklist guarantees we address everything from environmental impact to smart storage techniques. For pre-season checks, we inspect power cables and clean power terminals. Lubricating the moving parts like hinges guarantees smooth operation. Also, we must inspect mount rails, replacing them if necessary, and clean or replace anodes in the propeller drive motor. Regular maintenance involves checking for corrosion or wire heating, guaranteeing connections are clean, and motor performance is flawless. Additionally, after saltwater adventures, rinsing the motor helps avoid corrosion. At the season's end, our focus shifts to protecting gear from harsh elements. Proper storage techniques mean storing the motor in a dry spot, cleaning the propeller, and applying a lubricant to moving parts.

Here's a quick overview:

| Task | When to Do It | Purpose |

|---|---|---|

| Inspect Power Cables | Pre-Season | Guarantee no wear |

| Lubricate Moving Parts | Pre and Post-Season | Avoid rust and jams |

| Check for Corrosion | Regular Maintenance | Prevent connection issues |

| Store the Motor | End-of-Season | Protect from environmental damage |

| Rinse After Salt Water Use | Regular Maintenance | Minimize corrosive effects |

Embracing these practices releases the freedom to explore new waters confidently.

Professional Maintenance Services

Partnering with professional maintenance services can enhance the longevity and reliability of our trolling motors. Understanding that we've certified technicians working on our equipment gives us the freedom to focus on the open water, rather than being stuck troubleshooting motor issues.

Plus, when we choose services that offer service warranties, we're assured of quality work that lasts.

Imagine the peace of mind knowing:

- Certified Technicians: Our motors are in capable hands, managed by experts trained to handle major brands like Minn Kota and MotorGuide.

- State-of-the-Art Equipment: High-quality repairs and diagnostics are performed with advanced tools, ensuring our trolling motor operates at its best.

- Comprehensive Services: From propeller to wiring, the wide range of repairs means fewer worries for us and more time enjoying the water.

Relying on these services not only extends the life of our motors but also enhances their performance. Trusted technicians provide satisfaction guarantee on all repair work, ensuring quality and reliability. Quick solutions and customized packages allow for adjustments to fit any budget or need.

With the assurance of a satisfaction guarantee, we understand we're receiving exceptional care. So let's embrace the freedom to explore more, leaving the heavy lifting to the professionals.

Frequently Asked Questions

How Often Should I Replace My Trolling Motor's Electrical Components?

We should replace our trolling motor's electrical components every 5-7 years to guarantee component lifespan and circuit integrity. Frequent checks for wear and repair keep us free on the water, preventing unexpected malfunctions that could limit our adventures.

What Are the Best Practices for Storing Trolling Motor Batteries Long-Term?

Let's harness the power of smooth sailing by optimizing our battery storage. Sweep away grime with regular battery cleaning, dance through charge cycles, and guarantee a cool storage location. Embrace freedom with precise maintenance schedules and thoughtful security measures.

Can Solar Panels Be Used to Charge Trolling Motor Batteries Efficiently?

Yes, we can efficiently charge trolling motor batteries with solar panels by ensuring solar efficiency and panel durability. Selecting the right wattage offers freedom on the water without concerns about battery depletion. Let's embrace this sustainable solution!

Are There Any New Technologies Improving Trolling Motor Electrical Systems?

Imagine trolling motors audibly whispering in harmony We've got advanced materials boosting durability and smart controllers offering seamless, intuitive handling. This tech progression reveals incredible freedom on the water, transforming every journey into an unbounded adventure.

How Do I Accurately Measure Trolling Motor Electrical Consumption?

To accurately measure trolling motor electrical consumption, we should use voltage meters and current sensors. These tools give us control over monitoring power usage, allowing us to sail freely without unexpected interruptions. Stay informed, stay free.

Conclusion

In the end, maintaining our trolling motor's electrical system is kind of like tending to a garden; with regular care, it'll thrive and support our adventures. By keeping connections clean and batteries charged, we're ensuring smooth sailing on our fishing trips. Let's stick to our checklist, and our electrical system will stay shipshape. Like wise captains of old, we'll navigate any challenges, keeping our motors ready and reliable for the next big catch!